When it comes to restoring disruptions on the track, the manual planning for taking track out of service still causes hours of delay. Dutch infrastructure manager ProRail recently started using an application developed in collaboration with software company CGI. This reduces the process of requesting a Workplace Security Instruction (WBI) to a few seconds or minutes. Developing the DDIO (Data Driven Infra Withdrawals) application took two years of work.

DDIO can be used as an aid when applying for WBIs (Workplace Security Instructions) for defect recovery. The application works as follows: the app quickly calculates the desired extraction of tracks from service based on an indication of the location where the defect recovery should take place. Then, the application draws up a customised proposal with the accompanying measures, saving a lot of time in the process.

Milestone

After the necessary safety checks have been carried out, this customised proposal can be entered in ProRail’s Out of Service Planner (Btd planner). According to Hasna Hankari, Project Manager Projects and Implementation Asset Development and Information, the rollout of DDIO is a milestone for ProRail in data-driven work. “Normally, to apply for security instructions from the Out of Service Planner, you first have to manually determine your work area. For this you have to get a lot of information, especially in the form of drawings and schematics. For example, you have to indicate which parts of the track must be taken out of service and which safety measures are necessary for this. This manual process can take a few hours to a day.”

The DDIO systemn helps WBI applicants by calculating which area should be taken out of service itself. DDIO does this in a few seconds to a minute and immediately provides a proposal with the necessary safety measures. “Now you still have to manually enter the work area and the associated measures in the Out of Service Planner. But in the future, it is the intention that DDIO will ‘go under water’ and that it will be used automatically in the Out of Service Planner.” This means that the process is fully automated and that the system does the input and processing completely independently. Only the outcome will still appear in the form of an approved WBI.

Much faster

“Now you still have to submit a proposal to the Out of Service Planner, later you will receive a WBI with the push of a button. In the initial phase, DDIO is primarily an aid when applying for taking tracks out of service. You also no longer need a drawing of the track. This also saves a lot of time and means that trains have to stand still for a shorter time in the event of a malfunction because processes can be completed much faster.”

DDIO now goes live nationwide in the Netherlands and is used in case of failures without voltage. This is because the catenary data is not yet available. DDIO is therefore only used for defects that are not related to overhead lines. “I expect it will take another year and a half to two years before sufficient catenary data is processed. To do this, we have to translate drawings into data, which is a very labor-intensive process”, Hankari explains.

A global first

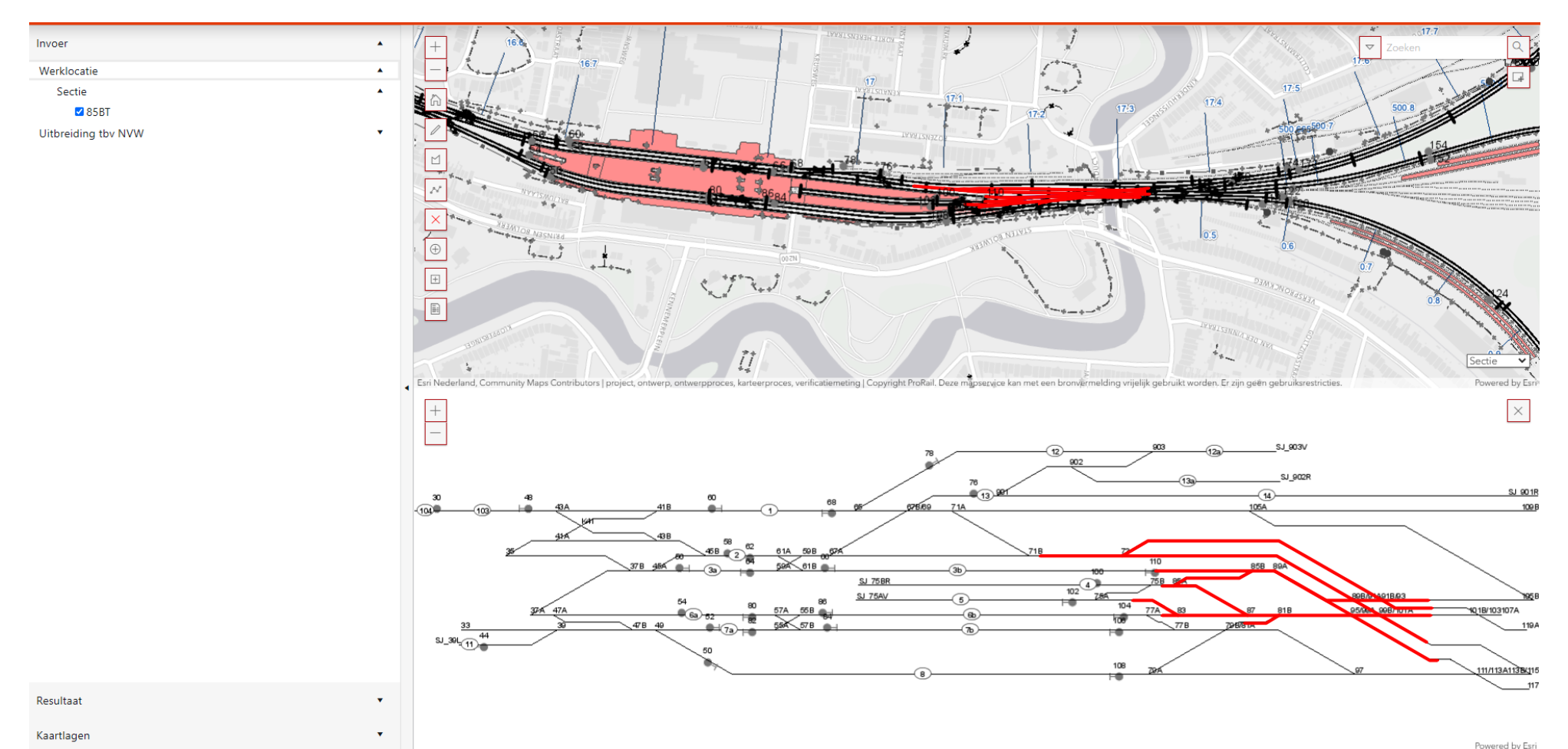

As part of this project, ProRail and CGI are also working on converting the geographic drawings and maps of the main railway network into schematics. “The advantage of a schematic compared to a map is that they are much more compact and you have a faster view of what you are looking for”, explains Hankari. “Now you can see at a glance how many points there are in a particular place and where the signals and signs are located. We are currently extracting the information from the drawings and maps that are important for defect recovery. In the future, we will expand the schematics with new objects, so that they can also be used for other purposes within ProRail.”

The schematic representation of the track maps in an application like this has never been achieved by anyone, according to Hankari. “This development is new at a global level. It really is a first. That is why there is a lot of interest from the rest of the world. Developers from all kinds of countries and companies congratulate us for having achieved this. We even gave a demonstration at a company in the United States. We are very proud of DDIO, especially because we have developed it in close collaboration with the parties that will soon be using it, such as contractors.”